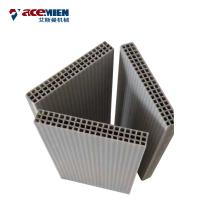

Hollow plastic template for concrete wall shuttering/scaffolding

formwork machinery

Advantages of pp Formwork

1. Manytimes reuse

Reuse 50-60 times ,6-8 times than plywood , totaly save cost more

than 50%.

2. Leight weight

Average weight 8.3kg/square meter ,make the work easily

installation quickly ,save labor cost and shorten the period of

project .

3. High strength,hardness,impact resistance-small check design

Small check design increase the srength , hardness and impact of

resistance ,reduce the weight.Shore Hardness(HD) is 70 .Impact

strength:Lateral pressure is 41.5KJ/m2 ,Vertical pressure is

85KJ/m2.

4. Easy demould and the best effect of casting molding

Smooth and clean surface make the demould easily .No need release

agent ,only tapping then the formwork will fall off .And the effect

of casting molding is very good .Also this finally shorten the

period of project.

Installation instructions:

• 1, Use the hollow building formwork intersecting surface laid

with 15 mm thick.

• 2, Wood square of the distance :

• 1, On the surface of the intersection (spacing: wood square

distance according to the thickness of the slab concrete, in

general, the thickness of less than 0.15 m floor (spacing is 200 ~

250 mm.

• 2,The shear wall (spacing: (spacing according to adjust the

spacing, height and thickness of the wall to wall height of 2800

mm, 300 mm thick wall, for example, using the formwork (15 mm

thickness spacing is 100 ~ 150 mm, if the shear wall, pillar width

more than 1 meter, must add the fixed frame.

• 3, Die shear wall and column puzzle when leaving no gaps,

internal Angle (the bottom of the wall) parts must have wood

square, beam, wall, formwork connection.Shear wall made 4 after the

mold must be assembled into the whole hoisting, then lay flat,

reduce labor intensity, forming effect is good.

Features of plastic construction formwork:

Hollow Plastic Formwork Dimensions |

Width x Length(mm) |

Thickness |

Weight(kg) |

| 915mmx1830mm |

14mm |

10kg |

915mmx1830mm |

15mm |

12kg |

915mmx1830mm |

18mm |

13kg |

1220mmx2440mm |

14mm |

18kg |

1220mmx2440mm |

15mm |

20kg |

1220mmx2440mm |

18mm |

25kg |

Advantage:

Comparision of hollow plastic formwork and other formworks

|

| Performace | Hollow plastic formwork | Modular plastic formwork | PVC plastic formwork | Plywood | Bamboo ploywood | Metal formwork |

| Wear Resistance | Good | Good | NO | NO | NO | NO |

| Corrosion Resistance | Good | Good | NO | NO | NO | NO |

| Tenacity | Good | Bad | Bad | Bad | Bad | Bad |

| Impact Strength | High | Easily broken | Normal | Poor | Poor | Poor |

| Absorbing water | No defoming | No deforming | Deforming | Deforming | Deforming | Deforming |

| Mold Release | Donot need | Donot need | Need | Need | Need | Donot need |

| Warp After using | No | No | Yes | Yes | Yes | Yes |

| Weight(kg/m2) | 6 | 10 | 15 | 8 | 8 | 12 |

| Recyclability | Yes | Yes | Yes | Yes | Yes | Yes |

| Bearing capacity | High | Easily broken | Normal | Normal | Normal | Normal |

| ECO-Friendly | Yes | Yes | Yes | NO | NO | NO |

| Cost of usage | Cheap | Expensive | Expensive | Expensive | Expensive | Very expensive |

| Reusable Time | Over 60 times | Over 60 times | 20-30 times | 4-6 times | 7-9 times | 90 times |

General Operation And Notes Of Instrument For formwork board system

:

- Method of use as well as wooden formwork, pvc bridge formwork

reinforcement direction with batten direction placed in cross

shaped.

- No need to smear the mold release agent before using board

formwork.

- When cast-in-place the flat plate, spacing between the keels should

be 20 ~ 25 cm, and the spacing between the wall plate and keels

hould be 10 ~ 20 cm. ACEMIEN formwork board system don't need

releasing agent.

- The seam-line between pvc bridge formwork should be taped.

- The length of nail should not be too long, generally about 30 ~ 35

mm.

- The strength to drive nailsshould be moderate.

- When removing the board formwork, please start from the small part

of one end, the support and the plates should be removed at the

same time aiming at preventing the template widespread drops, don't

let the corner drop on the ground vertically.

- The formwork board system accesses to be mixed used with wood

veneer, bamboo veneer and other material plate

FAQ

1. Q: Are you manufacture factory or a trader?

A: We are an industrial manufacture factory of plastic extrusion

machinery for years, which locates in Zhangjiagang city, China.

2. Q: What's your payment term:

A:T/T 30% in advance & T/T 70% upon sending the copy of Bill of

Lading, L/C 100%, or negotiate according to the order status.

3. Q: Can we visit your factory ?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case

4. Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients

should be satisfied first.

5.Q: Do you have any after-sale service ?

A: Yes,we have professional after-sale teamwork . any technical

question could be solved in 24 hours by our after-sale teamwork.

6. Q: How do you install your equipment in our factory ?

A: We have professional after-sale &installation teamwork, we

will arrange our engineer fly to ur factory install and teach ur

labor .

Our Packing and Shipping

Our Exhibition