PP materials plastic construction formwork building hardware making

machinery

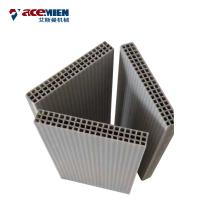

1. The best toughness

Can be used to make other different shapes and size

formworks.Bending strength:Lateral pressure 14Mpa , Vertical

pressure 21Mpa .Bending modulus:Lateral pressure 782Mpa ,Vertical

pressure 970Mpa.

2. Waterproof-hollow design

Hollow design make the formwork structural stability .Dimensional

shrinkage under heat:lateral 0.15% Vertical 0.13% .Diffcult

deformation, no mildew; Long-term immersion stratification in the

water, no bubbles, sheet size stability, especially suitable for

underground and damp environment.

3. Acid and alkali resistance, corrosion resistance

Very suitable for the engineering application in coastal areas,

mine, as well as seawall. It is need not do any preservative

treatment both in using and storing the formworks, which do not

pollute the concrete surface.

Installation instructions:

• 1, Use the hollow building formwork intersecting surface laid

with 15 mm thick.

• 2, Wood square of the distance :

• 1, On the surface of the intersection (spacing: wood square

distance according to the thickness of the slab concrete, in

general, the thickness of less than 0.15 m floor (spacing is 200 ~

250 mm.

• 2, The shear wall (spacing: (spacing according to adjust the

spacing, height and thickness of the wall to wall height of 2800

mm, 300 mm thick wall, for example, using the formwork (15 mm

thickness spacing is 100 ~ 150 mm, if the shear wall, pillar width

more than 1 meter, must add the fixed frame.

• 3, When the nail to the formwork from the formwork edge distance

15 ~ 30 mm, strength wants moderate, nail nails is 40 ~ 50 mm in

length, shoulds not be too long or too short.

• 4, Beam bottom of a piece of wood square must set aside 15 mm

seam allowance, wallboard made on wood square seam allowance, it

does not leak slurry and wallboard material saving.

Features of plastic construction formwork:

Hollow Plastic Formwork Dimensions |

Width x Length(mm) |

Thickness |

Weight(kg) |

| 915mmx1830mm |

14mm |

10kg |

915mmx1830mm |

15mm |

12kg |

915mmx1830mm |

18mm |

13kg |

1220mmx2440mm |

14mm |

18kg |

1220mmx2440mm |

15mm |

20kg |

1220mmx2440mm |

18mm |

25kg |

Advantage:

| Comparision of hollow plastic formwork and other formworks |

| Performace | Hollow plastic formwork | Modular plastic formwork | PVC plastic formwork | Plywood | Bamboo ploywood | Metal formwork |

| Wear Resistance | Good | Good | NO | NO | NO | NO |

| Corrosion Resistance | Good | Good | NO | NO | NO | NO |

| Tenacity | Good | Bad | Bad | Bad | Bad | Bad |

| Impact Strength | High | Easily broken | Normal | Poor | Poor | Poor |

| Absorbing water | No defoming | No deforming | Deforming | Deforming | Deforming | Deforming |

| Mold Release | Donot need | Donot need | Need | Need | Need | Donot need |

| Warp After using | No | No | Yes | Yes | Yes | Yes |

| Weight(kg/m2) | 6 | 10 | 15 | 8 | 8 | 12 |

| Recyclability | Yes | Yes | Yes | Yes | Yes | Yes |

| Bearing capacity | High | Easily broken | Normal | Normal | Normal | Normal |

| ECO-Friendly | Yes | Yes | Yes | NO | NO | NO |

| Cost of usage | Cheap | Expensive | Expensive | Expensive | Expensive | Very expensive |

| Reusable Time | Over 60 times | Over 60 times | 20-30 times | 4-6 times | 7-9 times | 90 times |

FAQ

1.Q: Are you manufacture factory or a trader?

A: We are an industrial manufacture factory of plastic extrusion

machinery for years, which locates in Zhangjiagang city, China.

2.Q: What's your payment term:

A: T/T 30% in advance & T/T 70% upon sending the copy of Bill of

Lading, L/C 100%, or negotiate according to the order status.

3.Q: Can we visit your factory ?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case

4. Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients

should be satisfied first.

5. Q: Do you have any after-sale service ?

A:Yes,we have professional after-sale teamwork . any technical

question could be solved in 24 hours by our after-sale teamwork.

6. Q: How do you install your equipment in our factory ?

A: We have professional after-sale &installation teamwork, we

will arrange our engineer fly to ur factory install and teach ur

labor .

Our Packing and Shipping

Our exhibition