Jiangsu Acemien Machinery Co., Ltd.

JiangSu Acemien Machinery Co., Ltd. is a brand production

enterprise which is the first batch of PVC roofing building

materials equipment, PP hollow construction formwork production

line in China, which focuses on plastic extrusion equipment and

plastic recycling equipment. The company has gathered a number of

outstanding talents and formed a high quality scientific research

team with the elite of Chinese and young science and technology as

the backbone. It has accumulated rich experience in product design

and profound theoretical knowledge in the continuous product

research and development practice.

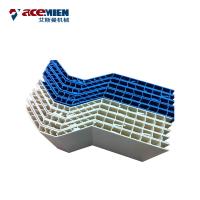

Our company concentrate on five series equipment, they are

Synthetic resin tile and PVC corrugated tile extrusion equipment;

PP hollow construction formwork production line; Artificial marble

sheet and profile extrusion equipment; Post recycling and

granulation equipment; Conventional extrusion equipment such as

pipe/profile/sheet; Auxiliary equipment such as

mixer/crusher/pulverizer.

JiangSu Acemien Machinery has become a large-scale and modern

national enterprise in the plastic roofing and building materials

industry. The company insists on the business philosophy of

"professionalism, integrity, win win and development", and

continuously improves technology strength and supporting

capabilities. In the era of Internet +, we will keep pace with the

times.